Model: HX-IBR & Corrugated Roof

Delivery time: 30 to 45 working days

Payment: 30% T/T deposit and 70% balance before shipment

Warranty period: 2 years

Operating voltage: 380V 50Hz three-phase (customizable)

WhatsApp: +86 13512486426

E-mail: lily@hx-machinery.com

We are Haixing Industrial Group Co., Ltd. We have been manufacturing roof sheet roll forming machines for over 20 years, so we are very professional and responsible in terms of both market and product.

This is an IBR 762 corrugated double layer roof sheet making machine, capable of producing IBR roof sheet and 762 corrugated sheets.

We can customize the machine according to your needs.

Currently, this machine is very popular in markets such as South Africa, Zimbabuwe, Burkina Faso and Cameroon.

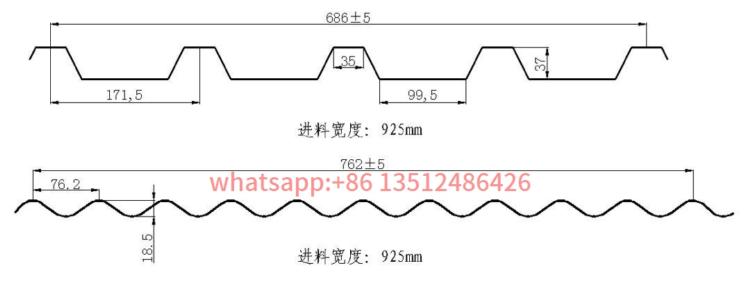

Below are the informations of IBR 762 corrugated double layer roof sheet making machine, as well as the profile dimensions of IBR and 762 corrugated sheets.

762 corrugated roof sheet.

IBR roof sheet

IBR and 762 corrugated roof sheets drawing

Machine parameters

| No. |

IBR 762 corrugated double layer roof sheet making machine |

|

| 1 |

Suitable to process |

GI, GL, PPGI, PPGL |

| 2 |

Dimensions |

8.7*1.6*1.7m |

| 3 |

Weight |

About 5T |

| 4 |

Main structure of the machine |

350mm H-Beam |

| 5 |

Side panel of machine |

16 mm |

| 6 |

Thickness of the raw material |

0.3-0.8mm |

| 7 |

Width of the raw material |

Max Material Width:1220 mm |

| 8 |

Drive mode |

Chain Wheel and Cycle Chain; Thickness:1 Inch

|

| 9 |

Productivity speed |

10-15m/min |

| 10 |

Rollers stations |

18 rows and 13 rows |

| 11 |

Rolling materials |

45# forging steel with chromium plate |

| 12 |

Diameter of the shaft |

Φ70mm (Solid shaft) |

| 13 |

Motor Power |

5.5 KW |

| 14 |

Pump Station Motor |

4 KW |

| 15 |

Material of the cutting blade |

Cr12,Quenched treatment 58℃-60℃ |

| 16 |

Control system |

PLC control |

| 17 |

Touch screen |

The touch screen 360 degrees |

| 18 |

Voltage |

380V three-phase power |

Sales Conditions

● Payment terms: 30% deposit, 70% balance after inspection before delivery.

● Production time: Around 30 working days after receiving the 30% deposit.

● Packing method: Naked packing in a 40-foot container, securely fixed with oil rope, control cabinet and all accessories sealed.

● Warranty: 24-month limited warranty. Components and parts are free during the warranty period.